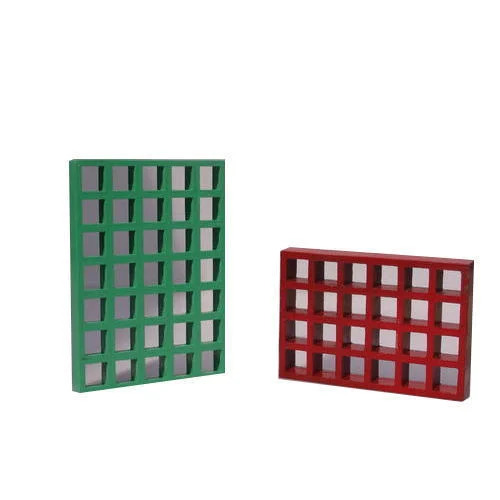

Molded Grating

Price 2000.0 INR/ Square Meter

MOQ : 10 Square Meters

Molded Grating Specification

- Usage

- Industrial

- Material

- FRP

- Surface Treatment

- Electrophoresis

- Size

- Customized

- Color

- Different Available

Molded Grating Trade Information

- Minimum Order Quantity

- 10 Square Meters

- Payment Terms

- Cash in Advance (CID)

- Supply Ability

- 5000 Square Meters Per Month

- Delivery Time

- 10 Days

- Main Domestic Market

- All India

About Molded Grating

Molded Grating is a type of structural material used in various industries for applications requiring lightweight, corrosion-resistant, and durable flooring or structural support. This is typically made from a combination of glass fibers and a thermosetting resin matrix, such as polyester, vinyl ester, or phenolic resin. One of the primary advantages is its lightweight nature compared to traditional materials like steel. Its combination of lightweight design, corrosion resistance, strength, and safety features makes it an attractive alternative to traditional materials in many industries. Molded Grating often features anti-slip surfaces, providing enhanced safety for workers in industrial environments where slip hazards may be present.

Enhanced Durability Through Electrophoresis

The electrophoresis surface treatment sets our molded grating apart by providing superior resistance to corrosion and wear. This process forms a uniform protective layer, extending the lifespan of the product, even under harsh industrial conditions. The result is a grating solution that requires less maintenance and offers long-lasting reliability.

Comprehensive Customization Options

We offer molded gratings in a range of colors and fully customizable sizes to meet unique industry demands. From load-bearing requirements to specific design and dimensional needs, each product is meticulously engineered to provide seamless integration and maximum efficiency across diverse applications.

FAQs of Molded Grating:

Q: How is the FRP Molded Grating manufactured?

A: FRP Molded Grating is produced using a process that involves laying fiberglass strands in a mold and saturating them with a special resin. Electrophoresis surface treatment is then applied, which enhances its resistance to corrosion and provides a uniform, protective finish.Q: What industrial applications are suitable for FRP Molded Grating?

A: This grating is ideal for use in industries such as chemical plants, water treatment facilities, food processing units, and marine environments because of its strength, non-conductive properties, and resistance to harsh chemicals.Q: When should I choose customized sizing for molded grating?

A: Opt for customized sizing when your project involves non-standard spaces, specific load requirements, or unique installation layouts. Customization ensures the grating fits perfectly and performs optimally in your industrial setting.Q: Where can Molded Grating be installed within a facility?

A: Molded Grating can be used for platforms, walkways, stair treads, trench covers, and flooring in areas exposed to corrosive substances or high-foot traffic, both indoors and outdoors.Q: What are the benefits of the electrophoresis surface treatment?

A: The electrophoresis treatment strengthens the surfaces resistance to corrosion, chemical exposure, and general wear, ultimately increasing the longevity and aesthetic quality of the grating.Q: How do you ensure product quality as a manufacturer and supplier in India?

A: We adhere to stringent quality standards throughout manufacturing and inspection processes. Each product is tested for structural integrity, chemical resistance, and dimensional accuracy to ensure reliable performance at the clients site.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in FRP And GRP Gratings Category

Pultruded Grating

Price 2500.0 INR / Square Meter

Minimum Order Quantity : 10 Square Meters

Surface Treatment : Electrophoresis

Color : Different Available

Material : FRP

Usage : Industrial

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free